Exploring the Intricacies of Stereolithography: Transforming the 3D Printing Landscape

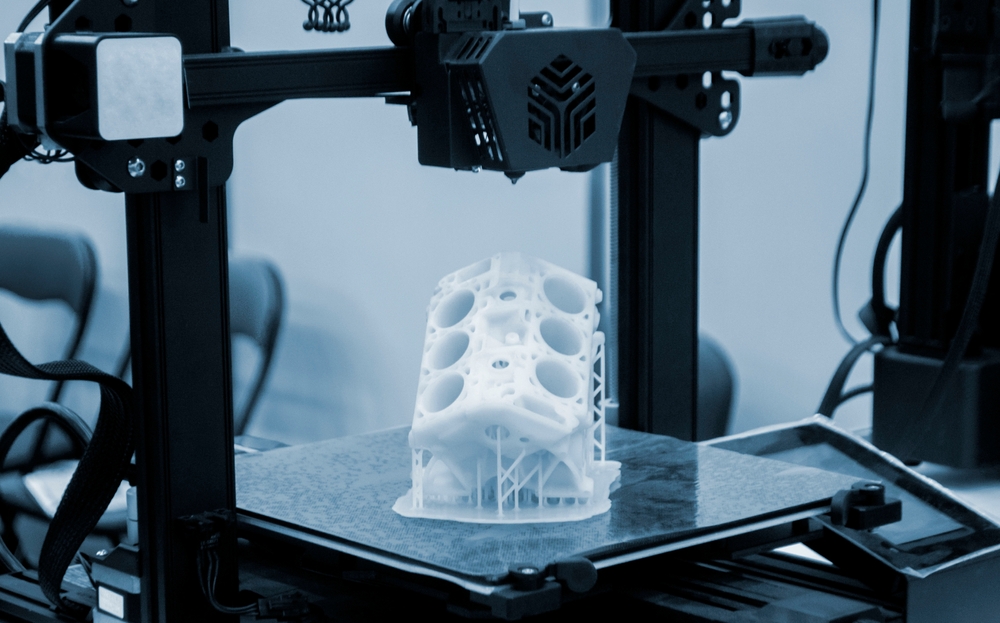

Introduction: Welcome to the future of manufacturing, where a digital design can be turned into a tangible object within hours. We're diving into the world of Stereolithography (SLA), a foundational technology in the 3D printing realm. Discover how this groundbreaking process is reshaping industries and redefining what's possible.

A Glimpse into the Past: Origins of Stereolithography

In the mid-1980s, a man named Chuck Hull revolutionized the manufacturing industry. Hull, the co-founder of 3D Systems, invented Stereolithography, a process that uses ultraviolet light to cure liquid resin into solid 3D objects. His invention marked the birth of 3D printing, paving the way for an era of rapid prototyping and unprecedented design flexibility.

Breaking Down the Process: How Stereolithography Works

At its core, Stereolithography is a layer-by-layer process. It begins with a vat of photopolymer resin, which is sensitive to ultraviolet light. A laser beam, guided by a computer, traces a cross-section of the object onto the surface of the liquid resin. The exposed resin hardens instantly, forming a single layer of the 3D object. This process is repeated until the entire object has been printed, one layer at a time.

Current Innovations: Stereolithography in the Modern Age

Today, Stereolithography is used across a wide range of industries, from automotive and aerospace to healthcare and consumer goods. It’s particularly popular for creating high-resolution prototypes, as it can produce objects with exceptionally fine details and smooth surfaces.

A recent trend in Stereolithography is the development of new resins with different properties, such as flexibility or transparency. These innovations are expanding the range of applications for Stereolithography, enabling it to produce more diverse and complex objects.

Market Impact and Pricing: The Commercial Side of Stereolithography

As Stereolithography technology has matured, it’s become more accessible to both businesses and consumers. Industrial-grade SLA printers can cost anywhere from $10,000 to over $500,000, depending on their size and capabilities. However, desktop SLA printers are now available for under $1,000, putting this powerful technology within reach of hobbyists and small businesses.

While Stereolithography might not replace traditional manufacturing methods entirely, it’s certainly carving out a significant niche. It’s estimated that the global SLA 3D printing market will reach $1.6 billion by 2025, reflecting the growing demand for this versatile technology.

The Road Ahead: Future Prospects for Stereolithography

Looking ahead, Stereolithography is poised to play a crucial role in the future of manufacturing. Researchers are exploring ways to speed up the printing process, broaden the range of materials, and improve the durability of printed objects. There’s also exciting potential in fields like bioprinting, where Stereolithography could be used to create custom prosthetics or even human tissue.

In the end, the power of Stereolithography lies not just in its ability to make things, but in its capacity to redefine the boundaries of what can be made. As this technology continues to evolve, we can expect to see even more innovative applications, further blurring the lines between the digital and physical worlds.